Down & Feather Menu

Quality assurance

For supplying safe and reliable quality of down, we test and inspect quality in each processing lot by our original testing methods in many aspects. Also, we do health test for each arrival lot of down after our processing and sanitary test of our factory same level of food industry. Our factory lines and facilities are fully automated and labor-free. Qualified staffs who pass necessary severe in-house exams give the orders to the lines. Each staff checks quality of down after each processing. We use natural down only. Never add usual cheating materials, cluster of down fiber from very short breed duck, down fiber from crash soft feather of duck and chicken, and binding chemicals.

Also, we consign all tests of down for whole processing lots to “UMOU Science Lab (USL).” USL is registered as the first certified testing organization in Japan, which is registered by Japan National Laboratory Accreditation system (JNLA)standard for JIS1903 (testing method of down & feather).One of USL branches is located in our factory. Fully processed down is analyzed at on-site branch of UMOU Science Lab. USL is an independent laboratory formally certified by International Down &Feather Bureau (IDFB), and the first authorized lab for JIS1903 (down & feather analysis) by ISO/IEC17025.

USL tests the composition, filling power and down power in accordance with “JIS L1903.” We check down by original unique testing methods including safety & heath test and set strict quality standards. We check our all processing lots by various analyzing tests.

Inspecting the inner process by qualified professionals

Throughout the whole production process from the arrival of the raw down &feather to its delivery, in-house qualified professionals check quality at 10 places in our processing line with their pride.

Confirming the arrival of the raw Down & Feather

We aim to get unique and homogeneous raw down & feather(same breeding days, kinds, etc.) from each country of origin directly. However, down & feather is natural by-product, therefore, we cannot get the same quality of the down & feather each year even in the same origin, farm and month. For this reason, we confirm to match the specific kind and quality of waterfowls with arrival contents from our long-term cumulative database and experience of in-house qualified professionals.

Checking during the manufacturing process

All processing machines in our factory are made based on the new theories from analysis of down & feather. In conclusion, we accomplish the goal of non-staff processing with multiple security systems.

Even production program, developed by our long-term cumulative data, was chosen automatically, our in-house qualified professionals arrange machine settings in accordance with the humidity of the day and slight quality difference of down & feather. When the temperature & humidity is particularly high like making us uncomfortable, barbules of the down & feather are closed, which makes it hard to get rid of dander and dust from. Therefore, we have to stop the production when uncomfortable index becomes high. Besides, down & feather is easy to absorb small particles. If PM2.5 is over 30μg/㎥ outside, PM2.5 inside in the factory will also get higher in short time. We will also stop the production immediately for down not to absorb chemicals.

Also, by checking the lot of down & feather after cleaning the dust, we appropriately arrange the amount of soap to wash. Also, the most suitable program by operating the sorting machine is chosen properly, wind speed, movable parts by millimeters, feeding time & quantity of putting in down & feather into the machine. In-house qualified professionals add further adjustment to try to get the best result from checking the condition of the lot.

In order to produce clean down & feather, we perform the daily maintenance of the machine. For example, we have the largest machine. We get into the machine in order to clean the particular parts and check by sight. Surely, we have got the OHSAS18001(working safety & hygiene) certificate on working safety.

Checking products (Processed the Down & Feather)

The processed down & feather will be made to finish products to meet up with each customer’s need based on the analysis result of the testing laboratory. The down & feather is not always of the same quality even though they are from the same country of origin. That’s why we consider how to make such down &feather stable quality as same as the Industrial Standards. We developed our own technology and designed the unique blending machine to uniform the quality by two or more kinds of the down & feather.

Against the optimized program data from huge Data Base, qualified professionals make the perfect design with the current situation.

After blending the down & feather we check the resilience and black point rate of the down & feather in the dedicated bag by touching and visual observation. Last but not least, we check the no existence of smell in down & feather by burying our faces into the bags and smelling them before delivering to our customers.

Analyzing tests of the Down & Feather

We analyze the processed down & feather in UMOU science lab, which is the first lab certified by JIS. On various tests, we add our original testing requirements to JIS, and then thoroughly control our quality.

Composition contents test

This composition contents are to analyze the down & feather components. We separate the down & feather into 8 types, defined by JIS L 1903, (down, small feather, large feather, down fiber, feather fiber, damaged feather, land-fowl feather, residue), and then we compare its quantity by ratio. Furthermore, we separate down into three types: normal down, nestling down, and plumule down, and check the breeding condition, period, and processing status of waterfowls, including down quality.

Down power test

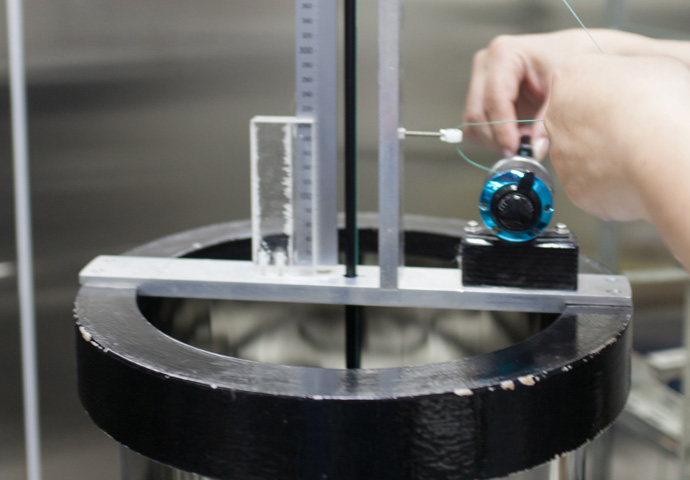

This Down power is to measure the resilience of the down & feather. In order to measure all samples of the down & feather in the same condition, there are pre-processed by the steamer and dryer. We also keep it at 20°C and the humidity at 65% in the testing room more than one day to stabilize the condition of the samples. We put the sample into the tester and then the disc on the top of it. We measure it by the scale how high the sample keep the disc.

Turbidity Test

The Turbidity of an aqueous extract is an indicator of the presence of material on the surface of down & feather. We put samples of the down & feather into the conical flask, add water to be fully penetrated, and then shake it for 45 minutes with the horizontal shaking machine. This filtered water is poured into the turbidity measurer, we check the water clarity on how to see the symbol of the measure’s bottom. The Japan Down and Feather Association has a turbidity standard, which has over 500 mm of the turbidity value. However, our turbidity standard has 2,000 mm for new down & feather, over 3000mm for recycled down & feather.

Other testing methods

Other testing methods for the down & feather with JIS L 1903 has Oxygen number, Fat & Oil and Moisture. Oxygen number is to measure the volume of organic matters attached on the down & feather, fat & oil is to measure the fat & oil in the down & feather. Moisture is to measure the moisture in the down & feather. In addition, we have some physical tests to check the smell, amount of dust, and water repellency of down & feather. Besides, we also conduct tests for the safety of down & feather. Especially, if dust, dander, and nutrients, etc. are attached on the down & feather, there become bait for bacteria and mold and cause them to multiply. Even worse, bacteria and mold are cause smell and allergies. Various testing has been performed to demonstrate the absence of these deposits on our washed down & feather, and the data is compiled. In order to ensure the quality of down & feather, filled into our products, we do our best to stabilize the high quality with an endless pursuit of down & feather.

Contact us

Kawada Feather Co., Ltd.

〒515-0303

3255, Yamaoyodo, Meiwa-Cho, Taki-Gun, Mie

TEL : 0596-55-2431 / FAX : 0596-55-4156

infokawada.net